Item | N380 | |

INJECTION UNIT | ||

Screw Diameter | mm | 60 |

Screw L/D Ratio | L/D | 25 |

Shot Volume(theoretical) | cm3 | 820 |

Injection Weight(ps) | g | 746 |

Injection Speed | mm/s | 280 |

Injection Rate | g/s | 721 |

Injection Pressure | MPa | 185 |

Screw Speed | rpm | 350 |

Injection and Displacement force | KN | 111 |

CLAMPING UNIT | ||

Clamping Force | kN | 3800 |

Open Stroke | mm | 700 |

Space Between Tie Bars(WxH) | mm | 725x725 |

Max.Mould Height | mm | 780 |

Min.Mould Height | mm | 320 |

Ejector Stroke | mm | 182 |

Ejector Force | kN | 91 |

OTHERS | ||

Max.Pump Pressure | MPa | 16 |

Pump Motor Power | kW | 90 |

Heating Power | kW | 31 |

Machine Dimension(LxWxH) | m | 7.5x2.2x2.1 |

Oitank Cubage | L | 700 |

Machine Weight | t | 19 |

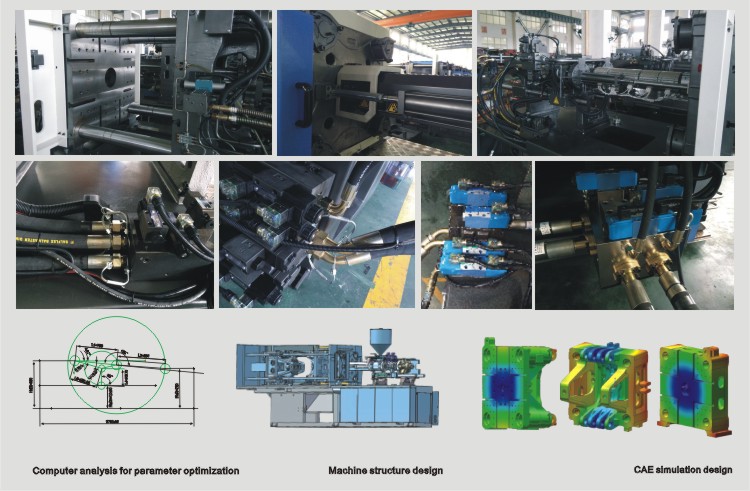

After more than twenty years development and accumulation,

Ongo has gathered a technology group mastering this

professional field and pursuing outstanding.

We devote ourselves to the product research

and technology development with pioneering and innovative spirit,

and have several patents already.

Introducing ltaly advanced technology,

in the mean time,we digest and absorb it continuously,

as well as combine with our own innovation ability to realize

second development in order to meet the changing market  needs.

needs.

In the survival of the fitest competition,

we are forward developed by plowing various difficulties.

Based on more than 10 years design experiences,main

parts as platen are analysed and designed by CAE simulation

technology to ensure the high quality and the reliability of the

products.

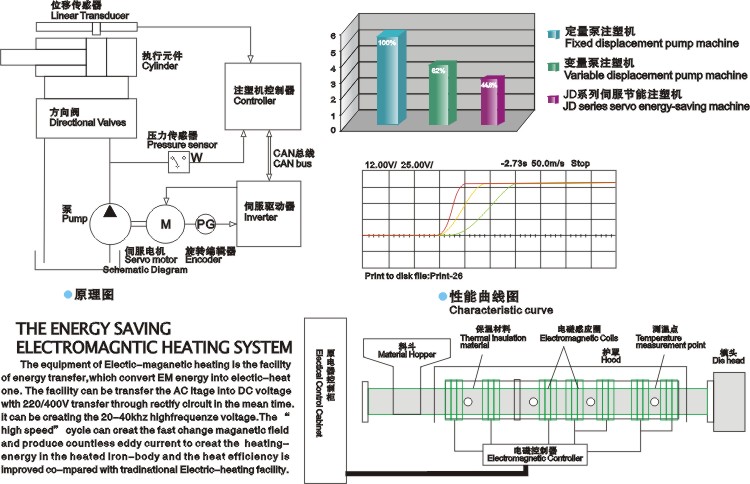

PRECISE AND ENERGY-SAVING SERVO

MACHINE JD SERIES

Equipped with high performance servo motor controlling

system,the machine's output power can vary in accordance

with the loading changes,which reduce energy consumption

and noise.The motor rotates at lower speed in holding pressure

stage,and doesn't work in cooling time.

THE ENERGY SAVING

ELECTROMAGNTIC HEATING SYSTEM

The equipment of Electic-maganetic heating Is the facility

of energy transfer,which convert EM energy into electic-heat

one.The facility can be transfer the AC Itage into DC voltage

with 220/400V transfer through rectify circuit in the mean time.

it can be creating the 20-40khz highfrequenze voltage.The“

high speed”cycle can creat the fast change maganetic field

and produce countless eddy current to creat the heating-

energy in the heated Iron-body and the heat efficiency is

improved co-mpared with tradinational Electric-heating facility.

![]()

High-grade Plastic Injection Molding Machine

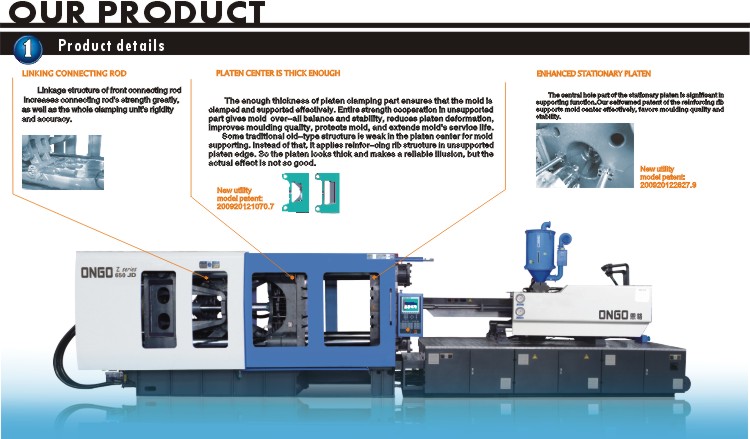

LINKING CONNECTING ROD

Linkage structure of front connecting rod

increases connecting rod's strength greatly,

as well as the whole clamping unit's rigidity

and accuracy.

PLATEN CENTER IS THICK ENOUGH

The enough thickness of platen clamping part ensures that the mold is

clamped and supported effectively.Entire strength cooperation in unsupported

part gives mold over-all balance and stability,reduces platen deformation,

improves moulding quality,protects mold,and extends mold's service life.

Some traditional old-type structure is we ak in the platen center for mold

supporting.Instead of that,it applies reinfor-cing rib structure in unsupported

platen edge.So the platen looks thick and makes a reliable illusion,but the

actual effect is not so good.

ENHANCED STATIONARY PLATEN

The central hole part of the stationary platen is significant in

supporting function.Our selfowned patent of the reinforcing rib

supports mold center effectively,favors moulding quality and

stability.

SPECIAL CUSTOMIZED AND

OPTIMIZED CONTROL SYSTEM

According to our more than ten years professional

experience and control system supplier's technique,

we develop specialized and custo-mized contro

programto improve machine's overall performance.

INJECTION PREPLASTICATION SEAT WITH OIL COPPER SLEEVE

The preplastication seat reciprocates once in every injection motion.Normal

non-automatic lubricationi

n injection unit can't offer iubrication support to this

important motion.Thus,we use oil copper sleeve to make sure that injection

reciprocates well.Even without lubricating oil support,it can also slide excellently.

Considering cost,however,some materials without oil always cause hamful

effect to injection accuracy after a period of time.

CLOSED BASE STRUCTURE

Compared with opened structure,the closed base

st-ructure is neater and protects components better to

avoid any damage by crash.It also improves operation

safety.

AUTOMATIC MOULD ADJUSTMENT

Automatic mould adiustment device is convenient

for customer operation.

SEALED STRUCTURE WITH CONE SURFACE

In line with famous international bra-

nds,sealed structure with cone surface in

connection position of high pressure oil

pipe improves sealing reliability greatly

SPRAY PLASTIC IN OIL TANK

Spray plastic in oil tank makes it clean,and what's more,it

prevents oil tank to be corroded for long time,extends hydraulic oil

service time effectively,and decreases customer's use-cost.

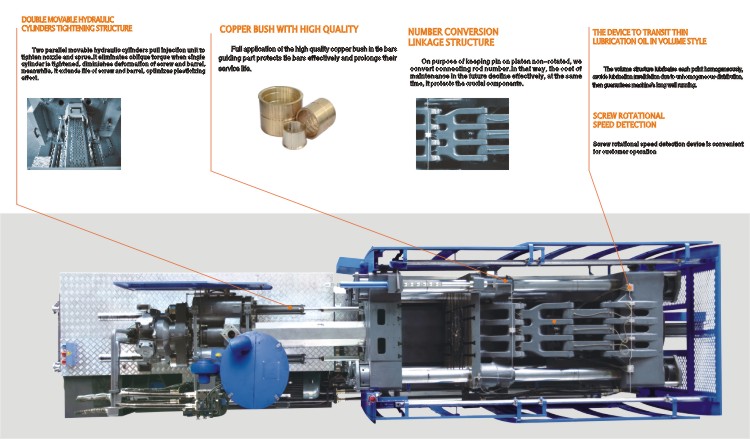

DOUBLE MOVABLE HYDRAULIC

CYLINDERS TIGHTENING STRUCTURE

Two parallel movable hydraulic cylinders pull injection unit to

tighten nozzle and sprue.It eliminates oblique torque when single

cylinder is tightened,diminishes deformation of screw and barrel,

meanwhile,it extends life of screw and barrel,optimizes plasticizing

effect.

COPPER BUSH WITH HIGH QUALITY

Full application of the high quality copper bush in tie bars

guiding part protects tie bars effectively and prolongs their

service life.

NUMBER CONVERSION

LINKAGE STRUCTURE

On purpose of keeping pin on platen non-rotated,we

convert connecting rod number.In that way,the cost of

maintenance in the future decline effectively,at the same

time,it protects the crucial components.

THE DEVICE TO TRANSIT THIN

LUBRICATION OIL IN VOLUME STYLE

The volume structure lubricates each point homogeneously,

avoids lubrication invalidation due to unhomogeneous distribution,

then guarantees machine's long wellrunning.

SCREW ROTATIONAL

SPEED DETECTION

Screw rotational speed detection device is convenient

for customer operation

THE ENERGY SAVING

ELECTROMAGNTIC HEATING SYSTEM

The equipment of Electic-maganetic heating Is the facility

of energy transfer,which convert EM energy into electic-heat

one.The facility can be transfer the AC Itage into DC voltage

with 220/400V transfer through rectify circuit in the mean time.

it can be creating the 20-40khz highfrequenze voltage.The“

high speed”cycle can creat the fast change maganetic field

and produce countless eddy current to creat the heating-

energy in the heated Iron-body and the heat efficiency is

improved co-mpared with tradinational Electric-heating facility.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Injection Molding Machine

Plastic Mould

Auxiliary Equipment